Technical highlights

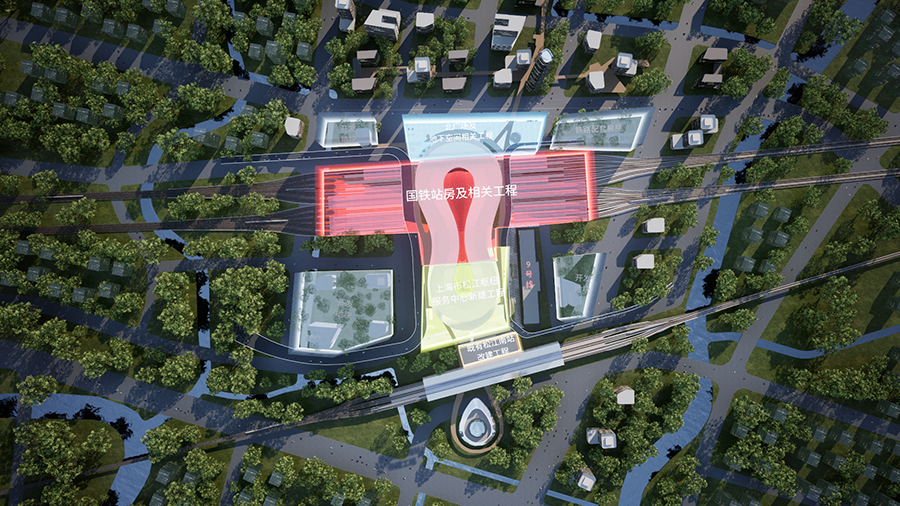

Shanghai Songjiang Station Service Center New Construction Project Design Highlights:

(1) Design of ultra-large deep foundation pit construction technology

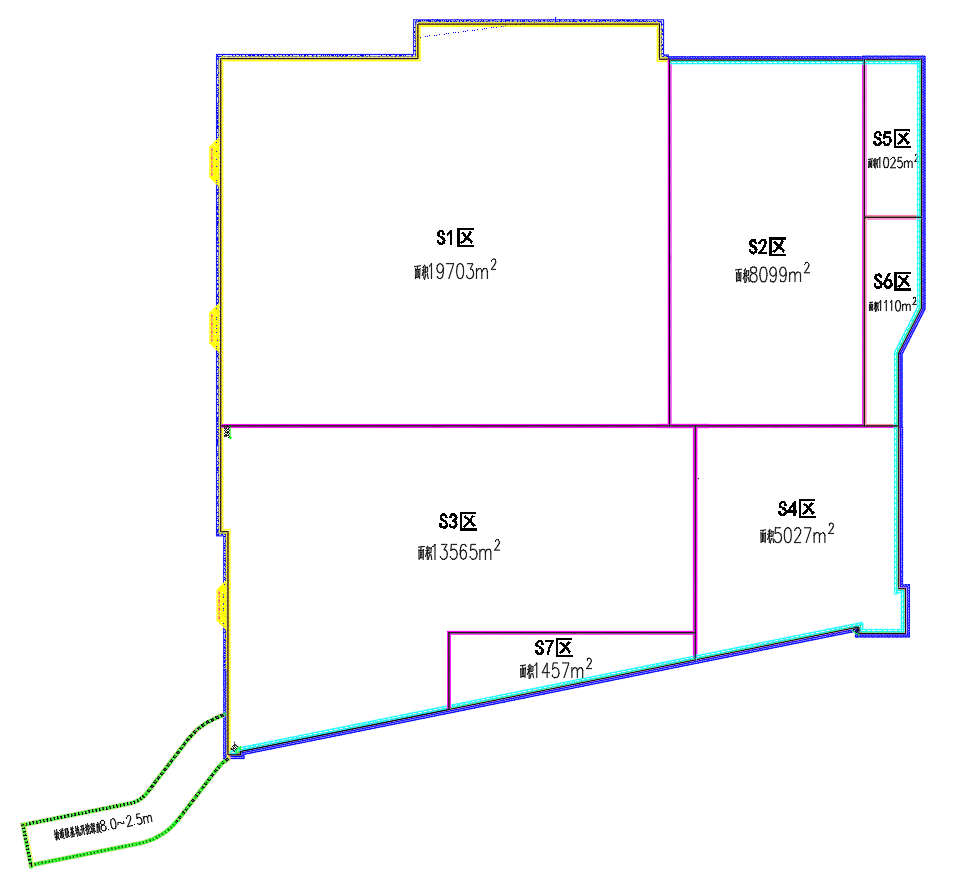

The east side of the foundation pit is adjacent to the existing operating Metro Line 9, and the outer edge of the foundation pit is about 6.5m away from the side wall of the Metro Line 9 station structure. The south side of the foundation pit is adjacent to the existing Songjiang South Station building, and the outer edge of the foundation pit is about 25.8m away from the outer wall of the Songjiang South Station building. The deep foundation pit is roughly trapezoidal, about 227~237m long from east to west, 192~236m wide from north to south, about 920m in circumference, 12.7~15.1m in excavation depth, and about 49,400 square meters in foundation pit area. The environmental protection level of the foundation pit on the east and south sides is level 1, and the deformation control requirements of the foundation pit are high. In order to ensure the quality and safety of the project, this project adopts the following technical measures:

1. Adopt the method of pit enclosure and pit excavation to reduce the adverse effects of large-scale excavation on the existing subway. The foundation pit is divided into four large pits S1~S4 and three strip pits S5~S7. The overall construction process is S1, S4→S2, S3→S6, S7→S5.

2. During the construction process, process test piles are carried out on TRD, three-axis mixing piles, and ground-connected walls to optimize construction parameters, reduce soil disturbance, and ensure the safe operation of subways and national railways.

3. The subway side is supported by ground-connected walls + one concrete support + three steel supports with axial force automatic compensation system. At the same time, the pit is fully reinforced to further reduce the deformation of the retaining structure and the surface settlement outside the pit.

4. The high-speed rail side uses ground-connected walls with large retaining stiffness and good integrity + three concrete supports for support. The concrete support uses a prestressed concrete servo system to effectively reduce the impact of foundation pit excavation on the existing station building.

(2) Application of BIM technology

By taking advantage of BIM visualization, the design concept of the design unit can be more easily conveyed to all participating units, which also facilitates the decision-making of the construction unit in the design scheme stage. Digital simulation of the construction process is carried out. In view of the complex installation difficulties of special-shaped hyperbolic roofs and curtain wall projects, digital simulation and plate pre-laying technology are used to ensure the accuracy and high-energy installation of the construction. In view of the characteristics of multiple installation projects, complex pipelines, and multiple intersections, the in-depth use of BIM technology is deepened and refined to ensure the digitization, informatization, and standardization of building entities, production factors, and management processes.